Gas Value Chain Optimization - The sustainable future of energy

Posted: August 24, 2021

Energy is important to humanity. But, as our world continues to change and develop, the needs of humanity must also change. In recent years, there has been an increased push for more sustainable energy sources that reduce global impact on climate. That’s why gas is so important. And that’s why the gas value chain has also shifted to accommodate this shift in demand.

Gas is a fossil fuel that’s primarily composed of methane molecules but may contain myriad other hydrocarbons, rare gases and contaminants such as hydrogen sulfide and carbon dioxide. It exists in pockets underground forming from the decomposition of organic matter along with heavier hydrocarbons. It can not only be used in its gaseous form, but also in liquid form. Liquefied Natural Gas (LNG) is colorless, odorless, non-toxic and non-corrosive. In the liquefied state, it can be stored or transported at atmospheric pressure. It takes up about 1/600th the volume as if it were in gas form. Its only hazards are flammability after vaporization into a gaseous state and asphyxia when heavy hydrocarbons remain in the liquefaction process.

Gas is a key part of our sustainable future as it provides cleaner energy than coal and fuels derived from oil with less CO₂ emissions. Sulfur dioxide, nitrogen oxide, mercury compounds and particulate matter are also emitted at lower rates when burning gas rather than coal. The advantages of using gas over traditional fossil fuels such as coal or diesel are clear in the emissions category. The gas value chain starts at wells that are tapped into reservoirs and then gathered and transported to processing plants for treatment of contaminants and recovery of gas liquids. When treatment and processing is completed, the gas can be transported via pipeline for shipment to its destination.

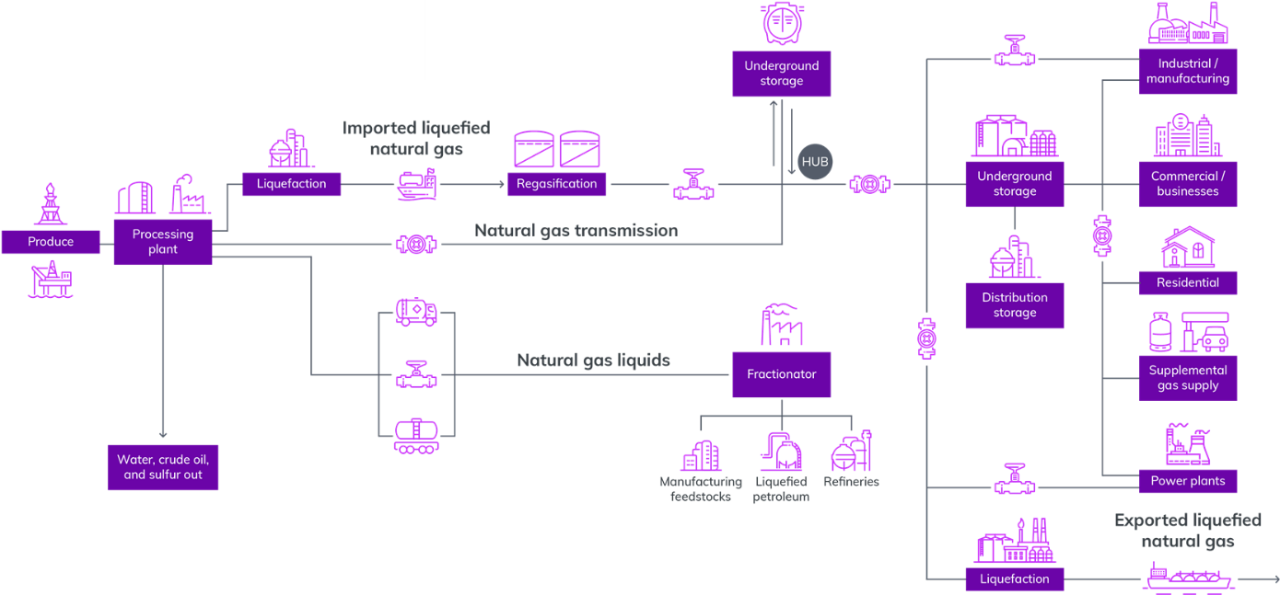

Figure 1. Gas Value Chain Optimization from Gathering to Consumption

Gas allows companies to be competitive economically while maintaining cleaner air quality. Gas fueled power plants are the perfect partner for renewable energy because gas-fired, combined cycle power plants take less time to start, stop and ramp load than coal-fired plants. This means that when power generation from renewables, such as hydro, solar and wind is insufficient to meet grid requirements, you can quickly start up a combined cycle gas plant until renewable power is sufficient to meet demand. Therefore, gas will play a significant role in many countries' future energy mix as we move towards renewables. Gas will bridge the gap during the transition to greener energy while traditional power generations plants are shutting down. AVEVA can help optimize the delivery of gas infrastructure, from sourcing and transport to processing and distribution during this transition.

There are multiple optimization opportunities across the gas value chain which include:

- Optimizing Network Planning & Scheduling

- Optimizing Fuel Usage

- Reducing Loses

- Minimizing Inefficiencies in Processing, Storage, & Transportation

- Reducing Equipment Downtime

Some operating companies may decide to develop their own solutions through research and development efforts; however, other firms may prefer to work with a commercial vendor who has expertise in developing software solutions.

AVEVA has solutions that are available to optimize the entire Gas Value Chain. AVEVA’s Solutions for Gas Value Chain Optimization helps minimize value leaks to optimize the value of each molecule of gas while meeting supply and demand requirements.

AVEVA’s value chain optimization solutions are available for the entire gas industry, enabling you to optimize gas processing, storage and transportation operations. Our solutions for the entire gas value chain are fit for purpose to meet global energy demand and climate change targets and have the following benefits:

- Improved operational efficiency

- Greater transparency

- Increase control of assets, people and activities

Having a single view of a complex asset means there will be significantly less room for error resulting in reduced risk exposure to financial loss or reputational damage. The significant investments being made in gas infrastructure worldwide require that the assets are sustainable not just today, but also tomorrow. AVEVA Gas Value Chain Optimization helps companies on both the supply and processing side as well as the demand side.

On the supply and processing side, AVEVA customers have seen savings of $1-1.5 MM/year/ MMTPA @ $7.5/ MMBTU outside of the United States. Gas Processing with NGL Recovery & Fractionation customers have seen savings of $1-1.5 MM/Year/MM SCFD @$3.0/ MMBTU in the United States. AVEVA customers on the demand side are seeing savings of $2.50-$5.00 /MMCF. This adds up to substantial monetary benefits over the course of a month or year.

Gas Value Chain Optimization helps you make significant, strategic improvements in operational efficiency that help generate lasting benefits for your enterprise – all while reducing costs and improving your bottom line.

Technical experts in science and engineering use AVEVA’s software from concept through operation support of real-world complex processes like those found in the Gas Value Chain — from upstream exploration and production of hydrocarbons to downstream natural gas processing & fractionation, storage and pipeline transmission networks.

Our extensive portfolio of industry-specific technological products provides the functionality needed to improve design efficiencies. improve operational efficiencies allowing day-to-day decisions made along your gas value chain have a direct and potentially substantial impact on profits, competition, market share—and the future of your business.

Related blog posts

Stay in the know: Keep up to date on the latest happenings around the industry.