Making Pressure Swing Adsorption (PSA) technology evaluation easier and faster

Posted: June 4, 2020

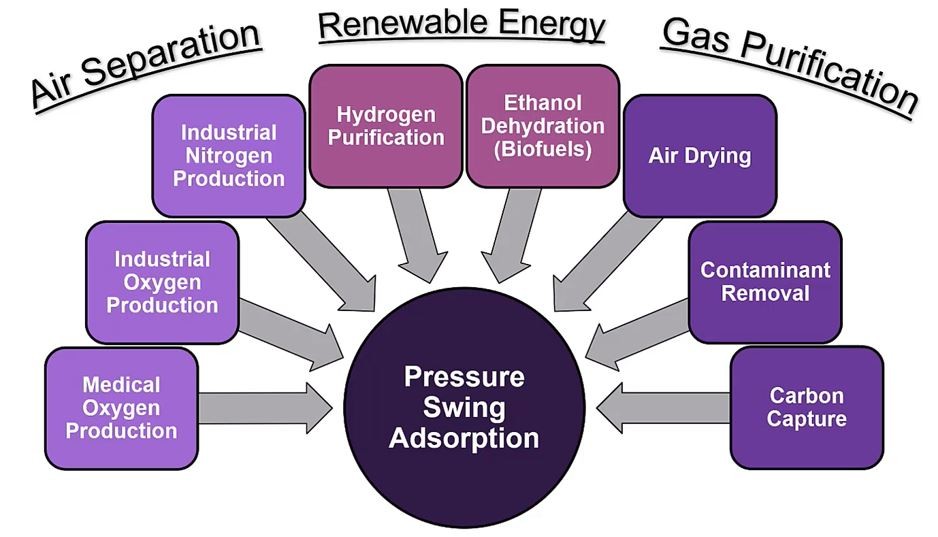

In times when we need to explore smaller, more efficient processes, and use alternative energy sources to enable more sustainable processes, the latest simulation tools and technologies need to be available for engineers and researchers. Pressure Swing Adsorption (PSA) is not a new technology. It´s been used for the last 60 years in several different fields, mostly air separation and purification. However, due to biofuels, carbon capture, and Process Intensification, interest in PSA is rising.

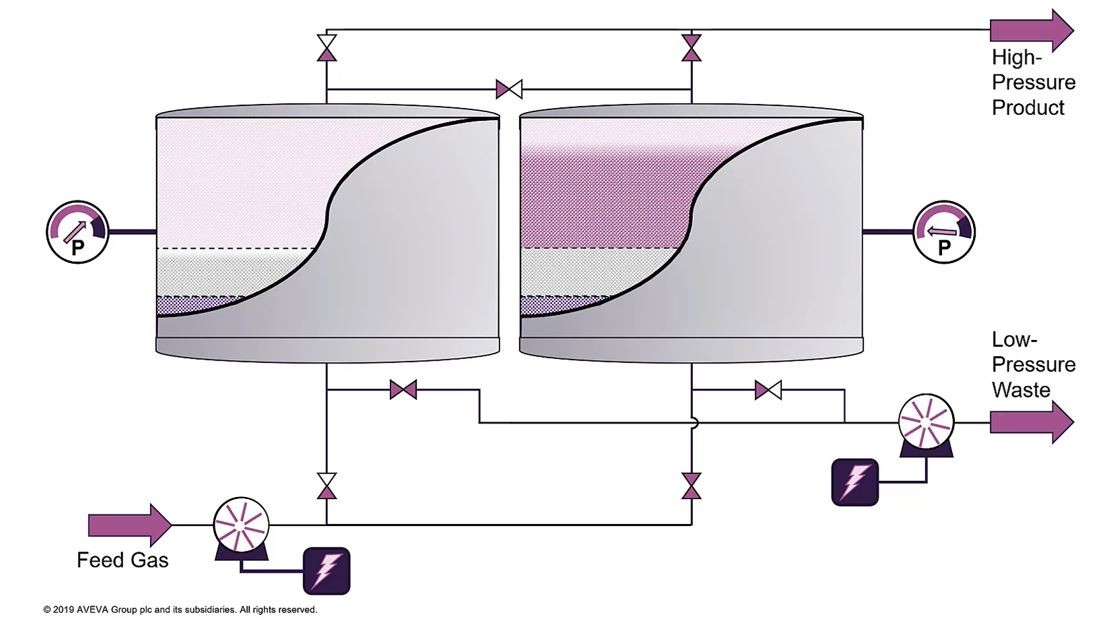

PSA uses mechanical energy to drive selective sorption and desorption of gas phased components from the bulk to the solid adsorbent. The result is that production streams return rich with one or more of the gas components. The mechanical power is expensive, but the pressure changes are fast, which means equipment is smaller with a lower capital cost and higher productivity. That makes it competitive for moderate throughput separation with high purity requirements. But the moving front in the bed presents a modeling problem, so few commercial process simulators have standalone models and those that do have steep learning curves and require a high level of expertise to use them.

The Adsorption Library Modeling in AVEVA Process Simulation (formerly SimCentral) makes PSA modeling more accessible. A unique user experience allows you to build and analyze models easier and faster. The learning curve is significantly lower than with other process simulators, and you don´t need a Ph.D. in PSA to use it!

In this video, you will learn why AVEVA Process Simulation (formerly SimCentral) is the best tool to model and evaluate PSA technology through demonstrations with the real software platform, and how you can connect your simulation with a Unified Engineering platform and obtain extra value from your application.

Special thanks to Dr. Alberto LaCava, St. Peter´s University, Ian Boys, AVEVA, and Michael Sees, AVEVA. Dr. Alberto LaCava is an industry expert, and his experience includes computer simulation of industrial gases, gas separation, gas purification, adsorption, catalysis, and pressure swing adsorption. Ian Boys is an expert in chemical process simulation, with extensive experience of both industrial applications and software design. Michael Sees created the PSA proof of concept in AVEVA Process Simulation as an engineering intern at AVEVA while receiving his chemical engineering Ph.D at Texas Tech University.

Click here to learn more about the AVEVA Process Simulation.

Discover how AVEVA’s end-to-end Digital Transformation solutions for Chemicals empower you to drive performance, improve asset utilization, and lower cost per unit at https://www.aveva.com/en/industries/chemicals/

Related blog posts

Stay in the know: Keep up to date on the latest happenings around the industry.