ACCIONA develops and manages sustainable infrastructure solutions globally, with a focus on renewable energy. The company created its water control center, known as CECOA, to improve its water facilities. It used AVEVA™ System Platform tools to build digital solutions that unify people, processes, and assets for continuous operational improvement. The system uses real-time SCADA to retrieve information from ACCIONA’s facilities around the world, allowing workers to know what is happening in each plant.

Challenges

Processing water more efficiently to address water scarcity

Reducing unnecessary chemicals to minimize environmental impact

Results

4.6%

reduced high-pressure pump energy consumption by 4.6%

16m3

increased production capacity by 16m3 per hour

reduced chemical usage by improving the way it measures pollutants

increased efficiency with better information sharing via the cloud

Transforming data into savings

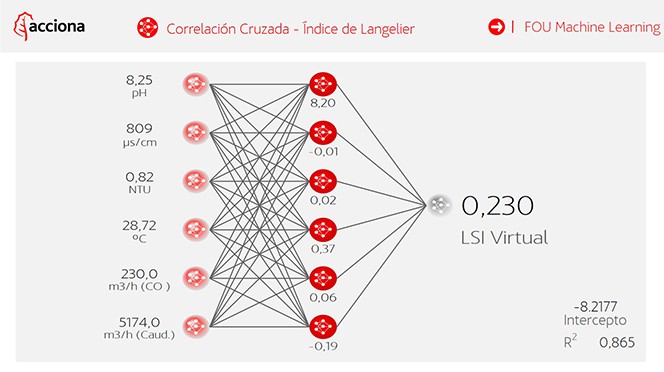

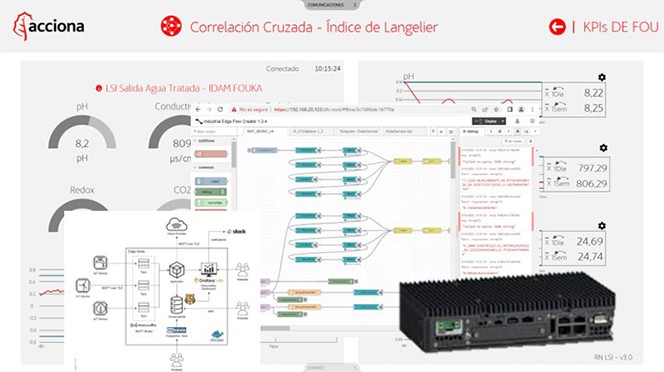

With AVEVA™ Historian, ACCIONA has improved the way it measures pollutants in its water. The company paired AVEVA Historian with a machine learning program that improves processes to ensure its operations are running as efficiently as possible. Some water parameters require a laboratory analysis, which can be a slow process and results are often too late to be useful. With virtual pollutant meters, which use machine-learning algorithms, ACCIONA can now predict the values for those parameters in its desalination and water treatment plants in real time. This has enabled ACCIONA to take action when required and reduce its use of chemicals.

Virtual meters allow ACCIONA to predict values for its water parameters, reducing its use of chemicals.

Virtual meters allow ACCIONA to predict values for its water parameters, reducing its use of chemicals.

ACCIONA also discovered new benefits from its software during the COVID-19 pandemic, when staff were confined to their own countries. With the connectivity of CECOA, the company could still remotely commission water plants outside of Spain, such as the Al-Khobar plant in Saudi Arabia. It used a digital twin to test the plant remotely, keeping production on schedule despite the pandemic. Using advanced analytics and artificial intelligence, the plant’s startup equipment, control system programs, water and electrical circuits were tested and put into operation with remote supervision. The technology helped ACCIONA analyze and optimize in real time, and empowered plant O&M teams to access the most relevant KPIs immediately. Using AVEVA™ Advanced Analytics to access this information has led to higher productivity and enabled early fault detection, which reduces the impact of faults and the time and money spent solving them. ACCIONA is also now able to share information more transparently with its clients, increasing clients’ confidence in its operations.

ACCIONA provides remote visibility into plant operations with cloud-based advanced analytics from AVEVA. With easy, secure access to its industrial information in the cloud, ACCIONA can share information with everybody who needs it in a fast and secure way. The company created KPI dashboards that display the most relevant information for each plant. This increases its O&M team’s ability to respond, enabling staff to access the information they need immediately—from anywhere and on any device. ACCIONA has also found clients have increased confidence in its operations, as it can securely share selected information with them more transparently.

"Five years ago, we embarked on a journey toward the digital transformation of water… We used AVEVA's software to build digital solutions that helped enhance production processes.”

-- Mariano Martin Tirado, Technical Leader and Head of CECOA, ACCIONA

Minimizing environmental impact by reducing energy usage

In its plant in the Canary Islands, ACCIONA created a prediction model for the production ratio of an osmosis rack to optimize energy consumption through energy recovery systems. The company uses advanced analytics, a cloud-based machine-learning platform, to predict equipment behavior, reducing energy usage and increasing production capacity. Algorithms enable the company to anticipate deviations in production and find the optimal operating point for the equipment based on operating conditions.

This ability to predict equipment behavior helps ACCIONA minimize its impact on the environment through its normal operation. These models led to a 4.6% reduction in energy consumption of the company’s high-pressure pump. It also enabled ACCIONA to increase the production capacity of the rack by 16m3 per hour, massively increasing efficiency without extra equipment.

ACCIONA’s CECOA center combines connectivity with data collection and analysis to optimize its treatment infrastructure.

ACCIONA’s CECOA center combines connectivity with data collection and analysis to optimize its treatment infrastructure.

Solution

ACCIONA uses AVEVA™ System Platform to enhance its water production processes. In its digital transformation journey, the company also uses AVEVA™ Historian, AVEVA™ PI System™, and Advanced Analytics through CONNECT.

Specialized decision support for water facilities

To extract the maximum insights from its data, ACCIONA is also collaborating with Schneider Electric on plant management system software, specifically focused on desalination. The plant management system uses a foundation of AVEVA PI System to optimize processes by monitoring process, maintenance, and supply data.

The plant management system will combine this data to create an interconnected system that extracts maximum insights. The systems will use visual representations of data, making it easier for users to understand and share complex information.

The company hopes the system will support long-term planning by providing insights into trends. It will incorporate predictive modeling, helping ACCIONA’s O&M team to anticipate future trends and outcomes. With data-driven insights, the company can make better-informed decisions, as well as assess and mitigate risks proactively.

“AVEVA System Platform provides a collaborative, standards-based foundation that unifies people, processes, and assets across all facilities for continuous operational improvement, so it was the ideal solution for our challenge.”

-- Mariano Martin Tirado, Technical Leader and Head of CECOA, ACCIONA

AVEVA solutions have transformed the way ACCIONA manages its water facilities. By reducing energy consumption and using predictive models to minimize its chemical usage, the company is achieving its goal of minimizing environmental impact and helping to solve the water scarcity problem. With AVEVA PI System, ACCIONA will be able to make more informed decisions, helping it identify further areas for cost and energy savings.

Product highlights

Contextualize operations with responsive, standards-driven, and scalable software for deploying advanced SCADA, MES, and IIoT. Unify people, processes, and assets.

AVEVA Historian provides a secure, high-performance database to consolidate disparate data sources and provide rapid retrieval techniques.

Maximize production efficiency, improve quality, energy efficiency, and throughput with cloud-based predictive and prescriptive insights.

AVEVA Insight delivers actionable information and Artificial Intelligence capabilities to help your teams improve asset reliability and operational performance.

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.