Cargill was already an AVEVA™ PI System™ user at over 200 plants globally. But the company also has over 400 more specialized facilities—such as grain elevators, protein processing plants, feed mills, ships and shipping ports—that can’t justify the high investment in the infrastructure used at its larger facilities. Cargill knew there was still value to be extracted from the data these facilities generated. The question was how to collect, centralize, and visualize this data to access that value.

Challenges

Collecting, centralizing, and visualizing data from facilities on the edge

Facilities such as feed mills, grain elevators, meat processing plants, ships, port terminals, etc. do not always have the technical resources on premises to support an AVEVA™ PI Server

Such sites may have only a few hundred data streams they really want to track but they come from a wide variety of automation systems and PLCs

Results

Standardized on system architecture and data model with minimal footprint that’s easy to run, maintain and scale for multiple types of technically modest facilities

Identified and addressed downstream bottlenecks and enabled root-cause analysis for productivity issues

Remote experts now able to view data in context and suggest improvements

Plant operators now able to monitor lab quality in real time and make necessary adjustments

Using AVEVA Edge Data Store, Cargill implemented an automated sampling and quality measurement instrument to monitor lab quality in real time using process data.

Using AVEVA Edge Data Store, Cargill implemented an automated sampling and quality measurement instrument to monitor lab quality in real time using process data.

Many sources, one solution: Collecting data at the edge

One of Cargill’s business enterprises involves the agriculture supply chain. Through this group, it trades green commodities, makes food ingredients such as corn syrup and chocolate, along with products for animal nutrition and health such as feed products and pet food, and produces finished protein and salt products.

Much of Cargill’s work is connecting farmers to consumers—it buys crops or animals from farmers, processes them, and then distributes the products to customers. This involves many facilities and transportation vehicles that are quite simple and don’t have on-board IT infrastructure to support the use of a full-fledged AVEVA PI Server—and with few data streams and few people on site at these locations, it doesn’t make sense for Cargill to invest in the same solution it uses at its larger facilities.

Working with AVEVA, the Cargill team developed a solution using AVEVA™ Edge Data Store to gather data at these facilities and feed it to the company’s centralized AVEVA PI Server, located at a site with more robust IT resources. Cargill collected data from PLCs at its smaller plants and grain elevators, then transferred the data used an OPC UA server running AVEVA Edge Data Store—using an OPC UA adapter—and connected this data to its central AVEVA PI System environment. It also deployed this solution on its ships, using AVEVA Adapter for Modbus and AVEVA Edge Data Store. One of the challenges managing data on ships is intermittent network connectivity. With this solution, the ship can collect and store data even when it’s out of range.

Solution

Deployed AVEVA Edge Data Store at facilities without extensive IT infrastructure to collect data from a variety of data sources and centralize it for the entire enterprise

Real-time visibility and improved processes

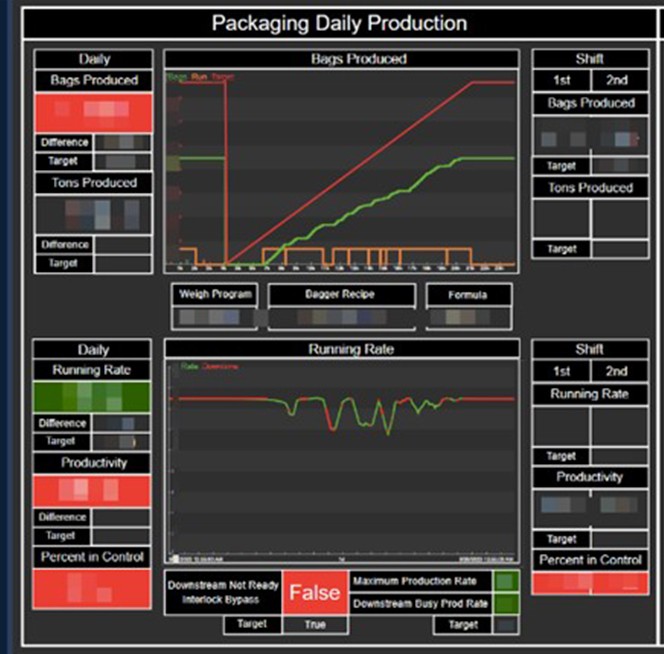

At one of Cargill’s packaging lines, it used AVEVA Edge Data Store to monitor and optimize its bagging process. Previously, most of the records at this and other plants like it were kept manually with pen and paper. This was how operators kept track of how many bags were processed and how production targets were being met. As Salil Rege, ANH Americas Smart Manufacturing Leader at Cargill, says, “When we deployed AVEVA Edge Data Store, it was the first time people got real-time visibility into our productivity. You could see what our targets were and how we were doing, so an operator or manager could see at any given instant: are we on track? Are we falling behind?” Using the notification feature, operators could also track alarms and get insights into downtime causes. This data could then be used to show management what exactly the issue is, what it’s costing the business, and how to fix it.

At another facility, Cargill used an automated robot to monitor quality. The robot collected samples and analyzed nutrient data, such as protein and fat. But the data was very localized. Someone at the plant could see it, but that was it. Using AVEVA Edge Data Store and an AVEVA adapter, Cargill pulled data from the robot using a structured JSON file and sent it to the central AVEVA PI Server. Now experts in other locations can look at the robot data and suggest solutions to improve the process.

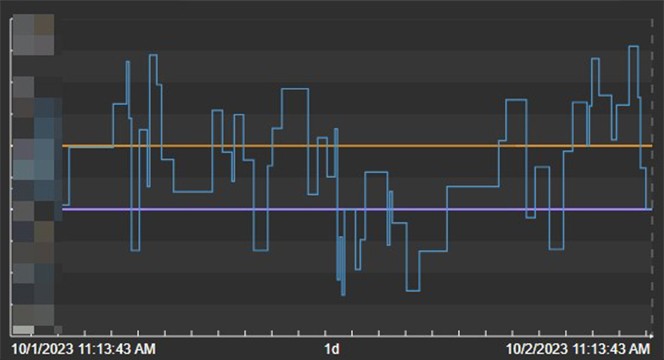

Cargill is also using this solution to track downtime at these same facilities. It was already using AVEVA PI Server to do this at its larger plants, but now it’s able to get information about downtime events using RtDuet and AVEVA Edge Data Store. The integration of AVEVA solutions with other tools and systems such as RtDuet—an application used to track downtime events—enables Cargill to easily track this downtime and address it.

Using AVEVA Edge Data Store on a packaging line to monitor KPIs and track downtime

Using AVEVA Edge Data Store on a packaging line to monitor KPIs and track downtime

When we deployed AVEVA Edge Data Store, it was the first time people got real-time visibility into our productivity. You could see what our targets were and how we were doing, so an operator or manager could see at any given instant: are we on track? Are we falling behind?”

—Salil Rege, ANH Americas Smart Manufacturing Leader, Cargill

AVEVA Edge Data Store is cost-effective and scalable. It doesn’t require local technical support. And it is natively integrated with the AVEVA PI Servers that Cargill already operates.

Cargill is still working to build more native visualization capabilities for AVEVA Edge Data Store, so the data it captures doesn’t have to be visualized in its centralized system. The company recognizes that AVEVA Edge Data Store is not a replacement for AVEVA PI Server—it’s a useful solution in specific cases where a facility’s footprint and resources require a different kind of approach. Cargill hopes to roll out this tiny but mighty solution to other facilities in its other business groups in the near future, cutting inefficiencies and optimizing operations so it can continue to nourish the world using the most sustainable methods.

Product highlights

AVEVA PI Server

Learn about the trusted, high-volume, and real-time data storage, contextualization, analytics, and notification engine at the heart of AVEVA™ PI System™.

AVEVA Edge Data Store

Collect, store, and access operations data from remote assets in harsh environments with Edge Data Store.

AVEVA™ PI System™

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.