As a global provider of water and wastewater management services, Inframark’s mission is to protect and replenish what it calls “the lifeblood of our planet and our communities.” Inframark knows that advanced digital tools and analytics are essential to this mission—which is why it partnered with AVEVA in a lighthouse project to combine cloud computing, data collected at the edge, machine learning, and advanced analytics to make predictions that would improve wastewater processes.

Challenges

Disparate data sources across the enterprise made it difficult to gain insights into operational efficiencies

Needed a software stack that enables any team in the enterprise to access and view the data

Wanted to use machine learning to discover and explore new insights from existing data

Results

gained the ability to organize and easily find the data needed to filter and contextualize it using a unified namespace

improved wastewater processes by implementing advanced analytics models, which were deployed in less than a day

predicted optimal asset behavior with advanced analytics, easily accessed in dashboards by clients, enterprise users, and other users, resulting in more efficient operations and less energy usage and waste

saved time and resources by using analytical models instead of relying solely on lab data

Lessons learned: Setting the right foundation

Inframark manages over 279 wastewater and 287 water facilities, with a combined capability of treating more than one billion gallons of water and wastewater daily and serving over four million water and wastewater customers. Across these many facilities are many disparate data sources, leading to data often stuck in silos. So one of the first challenges of Inframark’s Automation and Intelligence Division (Inframark A&I) was aggregating the data in order to apply machine learning and expedite insights from it.

One thing the Inframark A&I team learned right away was the importance of a good naming convention for their datasets. As a result of different integrators and approaches—combined with typos and users who don’t follow their own naming conventions—it was challenging to find the data they needed. So the team created a unified namespace using the asset rules within CONNECT data services to create tag names. The protocol allowed the team to parse stream names, use the data with metadata, filter it, contextualize it, and start building rules for machine learning.

Once the team had the data organized in this way, they used CONNECT visualization services to create dashboards and templates for individual assets and asset types—as Inframark creates new assets in the future, it can reuse those templates, reducing engineering time, improving efficiency, and driving consistency. And after they’d aggregated and organized the data, and visualized it in dashboards, it was time to use the data to make some predictions. So the team created a digital model using AVEVA™ Advanced Analytics to see how they might use process data with correlations and trends to predict optimum operational setpoints and plant conditions.

”As we expand this and roll it out to all our different customers’ facilities, we have a standard naming scheme so we can organize this data, we can find what we need to find, and it’s not just a big jumbled mess in the cloud.”

Eric Conder HMI Programming Manager, Inframark A&I Division

Using advanced analytics to predict key wastewater metrics

Using AVEVA™ Edge, the lighthouse team set up an HMI on the plant floor to mimic its existing SCADA system at their Bridgeport wastewater treatment plant and read the data from its PLCs. As CONNECT data services is easily integrated with AVEVA™ Edge Management, the team exported tags from that system and imported them into CONNECT—all 225 data tags, stored as streams—in half a day.

The team created models of plant assets with AVEVA Advanced Analytics available through CONNECT, using the in-built AVEVA wizard to walk them through the creation and training of the models. They focused on a couple different predictions using these models, including optimal nitrogen levels, dissolved oxygen levels, and biological oxygen demand in influent and effluent flows at the wastewater plant, all vital factors in keeping wastewater processes optimal.

“The nice thing about this is that we can reconfigure this on the fly without really having to visit the plant. [With] edge management in the cloud, we can add more data to CONNECT data services as needed. And then if we need to expand this to other facilities, we can do that as well.”

—Eric Conder HMI Programming Manager, Inframark A&I Division

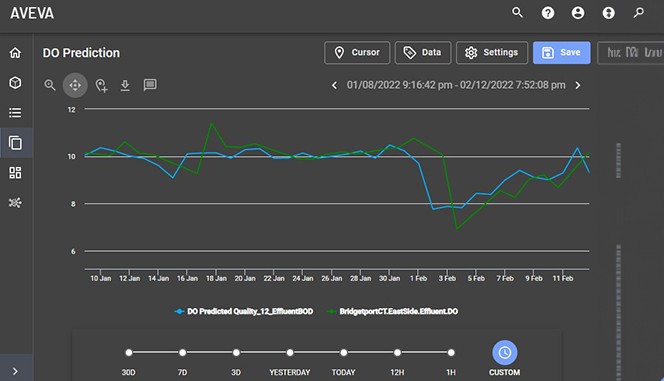

Inframark A&I explored datasets for modeling opportunities—in this case, looking at dissolved oxygen predictions to help reduce energy use.

Inframark A&I explored datasets for modeling opportunities—in this case, looking at dissolved oxygen predictions to help reduce energy use.

Inframark started refining the models by looking at how various inputs and factors correlate with the predictions. For example, the team looked at blower control to see if they could predict the optimum way to run the facility’s blowers to control the dissolved oxygen in its basins. Based on the conditions of the plant and the blower itself, they’re now able to predict the best way to run this blower. This kind of optimization results in more efficient operations, less energy usage and waste.

Pulling real-time and historical data into these models allows Inframark A&I to save time and resources, rather than relying solely on lab data, which generally takes about five days from the time of collection to get results. And as Inframark installs more sensors and collects more data, the models’ quality predictions will get even more accurate and reliable.

Solution

Inframark used AVEVA Edge, AVEVA Edge Management, and CONNECT data services to aggregate lab data, SCADA historian data, and real-time data into an accessible repository. Then, it used CONNECT data services and visualization with AVEVA Advanced Analytics to discover operational efficiencies and gain valuable insights.

Using cloud-based analytics on the plant floor

Looking ahead, Inframark A&I hopes to finalize its CONNECT visualizations and dashboards to share with its customers, so they don’t have to build remote access infrastructure through secure links or a VPN. Instead, Inframark can simply add them as a user and give them instant access. The team is also hoping to use analytics in the cloud accessed on-premises, so that an operator can look at the SCADA system and see any changes that need to be made right away on the plant floor.

Additionally, Inframark recognizes that operators across the 550 facilities it manages are going to be aging out of the workforce, and new operators coming in don’t necessarily have the hands-on experience to run these facilities—so it’s planning to create remote operations centers that collect and analyze data, look at predictions and plant process parameters across all 550 facilities, and feed suggestions with best practices to operators. As Inframark A&I continues to innovate, it will carry on finding new sustainable ways to keep the water flowing for its customers.

Product highlights

AVEVA™ Advanced Analytics

Maximize production efficiency, improve quality, energy efficiency, and throughput with cloud-based predictive and prescriptive insights.

CONNECT

Our industrial intelligence platform: securely access the broadest and deepest industrial software-as-a-service (SaaS) portfolio enhanced by the power of industrial Artificial Intelligence (AI).

AVEVA Edge

Formerly Known As Indusoft Web Studio

The rich feature set enables users to create intuitive, secure, and highly maintainable HMI /SCADA applications for any industry. AVEVA Edge HMI is ideal for OEMs, Machine Builders, Value Added Resellers, Discrete HMI/SCADA, or Process HMI/SCADA.

AVEVA Edge Management

AVEVA Edge Management enables software provisioning and management of remote devices across architectures e.g. IIoT, hybrid-cloud. Standardize across different locations. Monitor status and health.