Control Systems for Batch Poduction

Thanks to our experience and solution which we develop you can:

- Increase production efficiency by efficiently using existing production resources

- Manage multi-product and multi-stream production

- Constantly maintain product quality as per recipe specification

- Standardize recipes and manage production in multiple locations

- Process engineers will independently create and modify recipes, which results in a faster time to market for new products - stay ahead of your competitors!

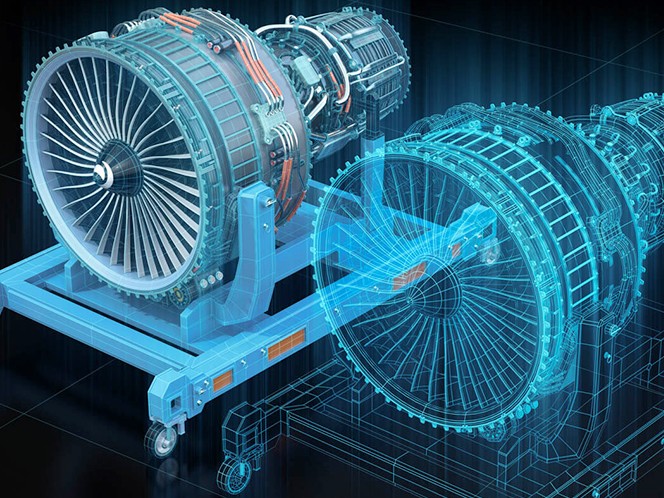

Process Simulators (Digital Twin)

Building a Control System for your production process or whole plant we create a simulator for your installation, tanks, reactors, etc.

Thanks to this approach you are able to:

- Verify the operation of the entire production process control system before implementation on site.

- Use the simulator to train a team of operators.

- Test new ideas and implement only tested solutions.

Case Studies - Chemical Plant

See how our customer Stepan benefits from our solutions.

Stepan is a leading producer of surfactants, polyurethane polyols, purity esters, fats, and oils.

Specifications

Type

Software

Industry Solution

Expertise Services

Packaged Services

Available on

Cloud

Mobile

PC

Tablet

Languages

English

Product Template

Expertise and Packaged Offering

Control-Service Jaromir Turlej

At Control-Service we implement innovative solutions in the field of automation of technological processes and industrial IT systems. In particular systems for batch production, advanced SCADA systems and utilities monitoring. Our services include: design and software development, on site assembly and commissioning, operators training and post-implementation service. Thanks to our database of objects, and innovations in line with the idea of Industry 4.0, we provide modern and scalable solutions. They are tailored to the current needs of the user and ready for easy development in the future. We create virtual simulators of production processes for most of the delivered systems. This approach to process automation enables stress-free training for operators on the virtual factory model (Digital Twin). It is also possible to test new solutions in comfortable simulation conditions without the risk of generating losses.

Related Products

AVEVA System Platform, formerly Wonderware

Contextualize operations with responsive, standards-driven, and scalable software for deploying advanced SCADA, MES, and IIoT. Unify people, processes, and assets.

AVEVA Historian, formerly Wonderware

Formerly Known As Historian

Empower people with high-fidelity historical data from operations, enabling them to solve problems faster, make better data-based decisions, and increase productivity.

AVEVA InTouch HMI, formerly Wonderware

Formerly Known As InTouch HMI

AVEVA InTouch HMI is HMI visualization software for operators to achieve real-time operations visibility. The world’s most widely used plant HMI for process monitoring and control.

Related Services

EVANS Control Room Expertise Services

Manufacturer of control room consoles, technical furniture, and security rooms. Discover your next console and control room solutions with Evans.