Unifying operations for mining

Make agile decisions across the entire mining value chain with the centralized view from AVEVA Unified Operations Center for Mining. Better predict inventories and blends of raw materials to improve recoveries and reduce the impact of logistic disruptions. Uncover value by pairing broad insights with context from production events and follow your operations from pit to port. Use these insights to augment the capabilities of integrated remote operations centers for mining value chains.

Agility and resiliency through operational awareness

Improve agility and decision-making across the entire mining value chain with a centralized view from AVEVA Unified Operations Center for Mining. Using a system of systems approach, it converges operations technology (OT), information technology (IT), and engineering technology (ET). By giving you a single pane of glass through which to view contextualized information, you can:

- Better predict inventories of raw materials blends

- Optimize production processes and produce inventory positions

- Identify operational deviations and production anomalies fast for quick recovery

- Reduce logistical disruptions and minimize loss

- Evaluate asset performance and equipment health

- Increase visibility and better manage environmental, safety, and governance (ESG) standards

- Follow your operations from pit to port

Unify data without losing context

Consolidate and align information from disparate sub-systems into a unified, 360-degree command environment. With a full view into pit-to-port operations performance, you can see and manage:

- Hierarchy of linked KPIs Truck fleets

- Workforce empowerment Incident reporting and SOPs

- Cross-functional collaboration

- Energy management

- Environment and waste management

Features

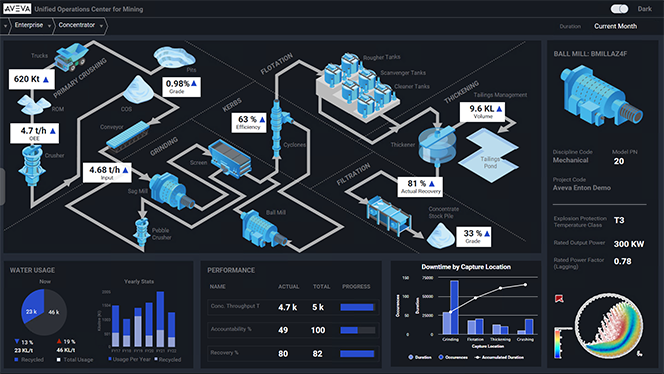

Map-based navigation

Start with a holistic satellite perspective of geographical operations and drill down into each asset and system. Use functional overlays and examine KPIs in real-time for more complete insight.

Increase awareness of operating conditions

Move from reactive mitigation to proactive assessment. Global data visualization allows you to prevent critical asset failure, respond to market demands, and ensure operational performance.

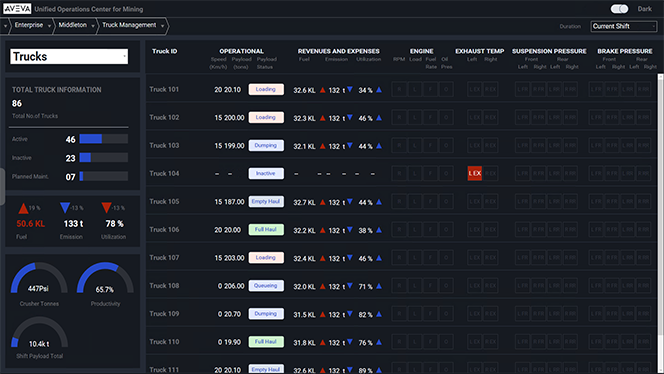

Fleet conditions and near-time status

View the status of different types of equipment in your fleet. For example, selecting trucks reveals detailed dashboards that highlight anomalous attributes by uncovering the underlying data provided by AVEVA™ PI System™.

Gain flexibility in scope and scale

Deploy to a video wall, multi-user workstation, or single desktop, depending on your users’ needs.

Improve production event visibility

Data sources like AVEVA™ Production Management and AVEVA PI System provide detailed insight into production-affecting events. Assess their broader impact on your business and associated operating units while monitoring resolutions in near-real time.

Single version of truth for business agility

Give workers actionable information in context. AVEVA Unified Operations Center for Mining uses all available data so teams can optimize decision-making, improve operations in real-time, and seek more sustainable outcomes.

Mining content and connectors

Get started quickly with graphics, layouts, and connectors specific to mining operations. Customize your application with your company branding and unique system attributes to accommodate different operations environments and business goals.

Leverage AVEVA’s expertise

Our software technology is purpose-built for industrial operations and engineering. We use best practices and templated design techniques that reduce development effort and drive industry-leading total cost of ownership.

Discover Latest News and Resources

Check out the latest news, blogs, events, webinars, and success stories.