AVEVA’s industrial software powers Capgemini’s Intelligent Industry solutions

AVEVA is a leader in sustainable industrial platforms and software, and Capgemini, an Endorsed AVEVA partner, is known around the world for its strong domain expertise and its long history of delivering enterprise solutions and services. Together, we bring packaged solutions and offerings to the marketplace that meet industrial companies’ requirements—pre-defined, proven, and ready for implementation.

Making an impact, together

We build bridges between businesses and the technologies they need to improve operations with trusted data.

Our initial service offerings provide proven value to supporting operational KPIs:

- Data-driven operations strategy and transformation

- AVEVA™ PI System™ at scale for operations

- Operations data hub set-up, integration, and management

- Use case library and factory

- Operations applications maintenance and support

How we engage with our clients

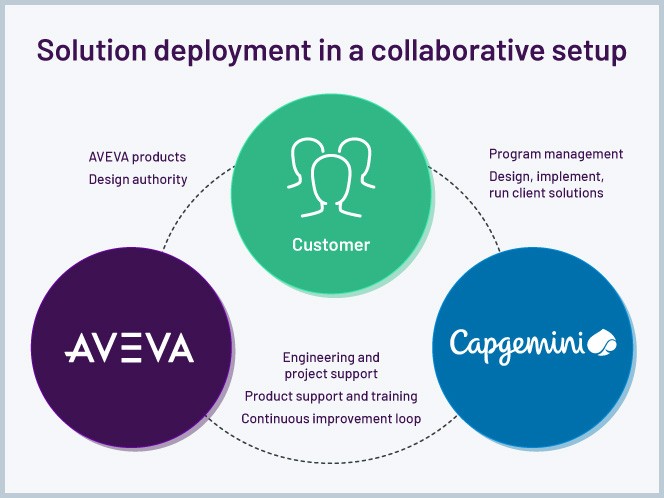

- Capgemini works with the client to create a holistic data strategy with solutions tailored to the client's needs

- AVEVA’s broad industry software portfolio is the foundation for creating solutions

- Capgemini teams up with AVEVA to provide engineering, project, and product support

We bring a unique combination of transformative capabilities—consulting, IT, OT, data, and cloud—and industrial solutions to help organizations achieve better operations and better outcomes.

We use our library of cross-industry use cases and our vertical expertise to develop software solutions purpose-built for the needs of industry.

With global capabilities and delivery factories around the world, we help leading organizations harness the power of data, AI, and cloud-native applications to unlock new value at speed.

Industrial software can help accelerate global decarbonization

Together, AVEVA and Capgemini Invent have laid the foundation of a new sustainability impact methodology. Read the white paper to learn about:

- The link between industrial and sustainability KPIs

- How a data-centric approach to operations enables circularity

- How digital solutions can turn sustainability into a competitive advantage

Simulate and optimize complex processes during design, and monitor and improve performance during operations.

Monitor and optimize process execution at the operations level, improving productivity & quality of production.

Automatically optimize process and energy systems to meet production specifications with reduced energy consumption.

Provide early warning notifications and diagnosis of equipment issues before failure, reducing environmental costs related to failures.